About Blackhawk Engineering, LLC

About Us

Welcome to Blackhawk Engineering, LLC, a pioneering force since 1974, dedicated to crafting superior tooling, dies, and special machines. Evolving over 5 decades, we have grown and diversified to become your ultimate destination for top-tier precision CNC machining services. Explore the pinnacle of innovation with us.

Blackhawk Engineering, LLC was founded in 1974 to design and build tooling, dies, and special machines. Over the next 50 years, our company has expanded and diversified to provide customers with the best precision CNC machining services available.

BHE’s focus on customer service, competitive pricing, and on-time deliveries has kept us at the forefront of the CNC machining industry.

Blackhawk Engineering, LLC

Over the Years

1974

Founded

- Blackhawk Engineering, LLC was founded in 1974 to design and build tooling, dies, and special machines. Over the next 50 years, our company has expanded and diversified to provide customers with the best precision CNC machining services available.

1985

CNC Lathes and Mills Purchased

- Additional CNC lathes and mills purchased to focus on machining service/short-run production parts.

1988

Machining Center Purchased

- Purchased a large horizontal machining center for agricultural differential housing.

1989

Certified Supplier

- Became the first recognized Certified Supplier to John Deere Waterloo Tractor Works for drivetrain casting machining.

1990

Specializing

- Blackhawk Engineering Production Group and Blackhawk Engineering Systems Group split into two separate entities and facilities, allowing for our focus on production machining.

1995

Expansion

- Completion of second building expansion, allowing us the needed space to focus on our expanding expertise in horizontal mill usage for six-sided drivetrain-type machining. Also, in 1995 we became the world’s No. 1 user of Hitachi Seiki Horizontal Pallet Changers.

1996

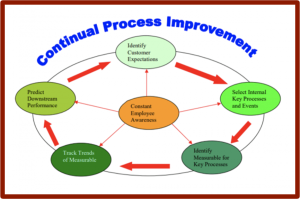

Improvements

- Introduced the Ford Quality Operating System (QOS) used to drive and improve BHE business practices.

1999

Achievement

- Achieved ISO 9000 registration.

2009

Certification

- Certified to ISO 9001:2008.

2011

New Addition

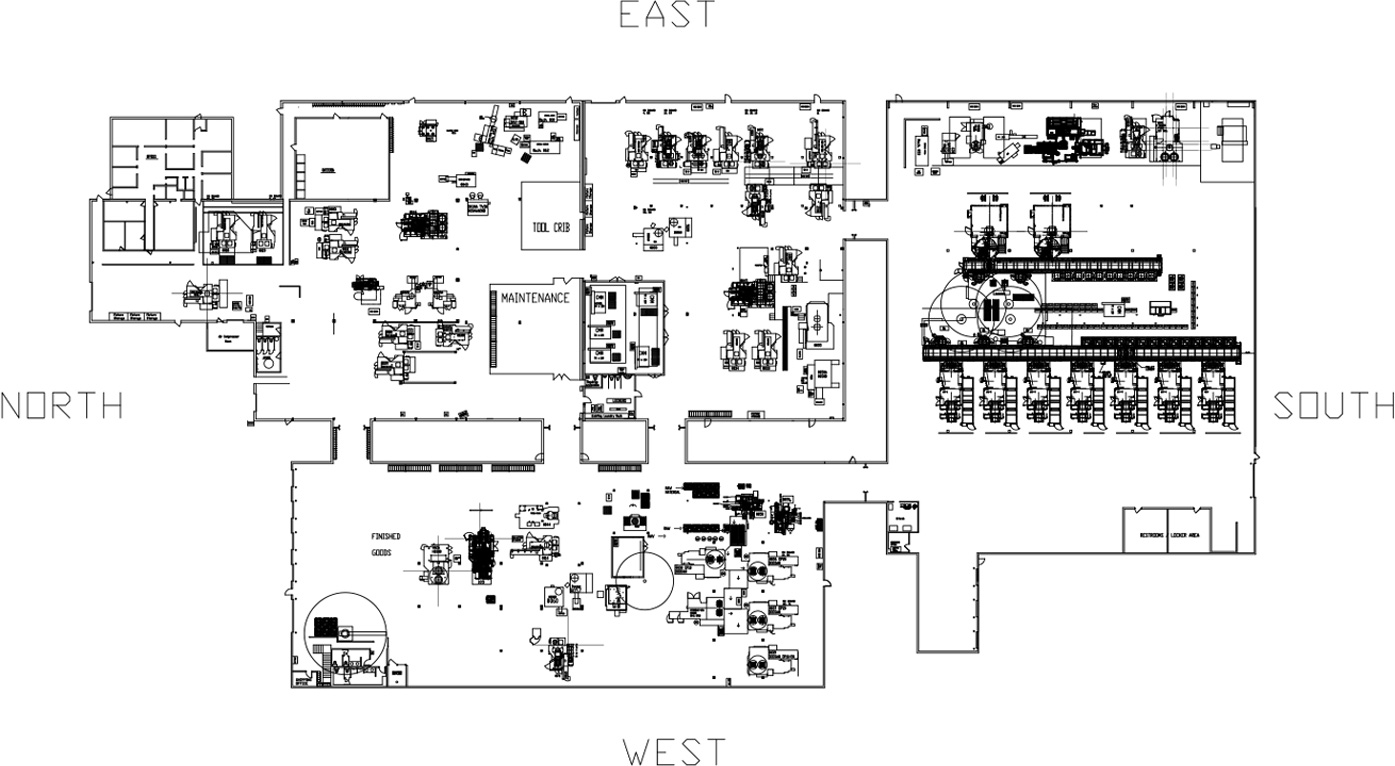

- 30,000 sq. ft. plant addition completed, build in response to high demand for our services

2013

Broke Ground

- Broke ground on a 40,000-square-foot facility, expanding our facility to 118,000 square feet.

2016

Receiving Dock

2018

Plant completed

- 40,000 sq. ft. plant addition completed, providing space for new opportunities and for further diversification.

2018

FMS Cell installed

2022

1st Robotic Cell

- 1st Robotic Cell installed NL 2500M and Halter Robot

2023

2nd Robotic Cell Installed

- 2nd Robotic Cell Installed Doosan 2600ST and Doosan HV400 Mill with Laser and Vision System.

2023

New Lighting Project

- New shop Lighting Project Complete